Fused cast block description

Fused cast block is made by the way of electric smelting tech. With the different ingredients of raw material, fused cast block can be divided further as fused mullite block, fused AZS block, fused alumina block, fused high zirconia etc. Fused refractory materials is widely used in the field of glass industrial, steel & iron manufacture, nonferrous metals smelt, building material industry and other industrial furnace.

Huachen Company as a profesional manufactuer of fused cast block, we have pass the ISO internation certification, with the high quality and long service time of our fused cast block, our blocks have exported to more than 15 countries.It si very welcomed fused cast block in the marketing.

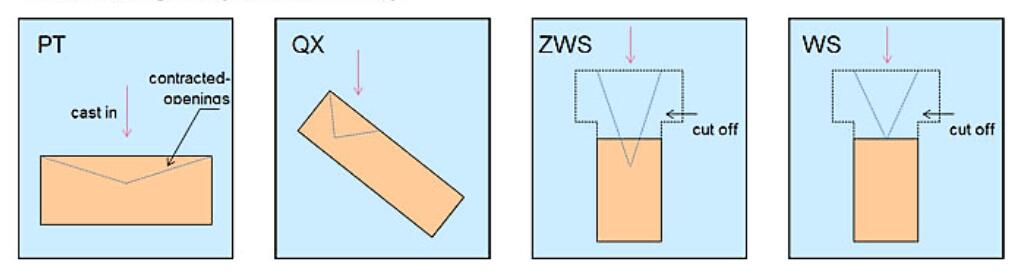

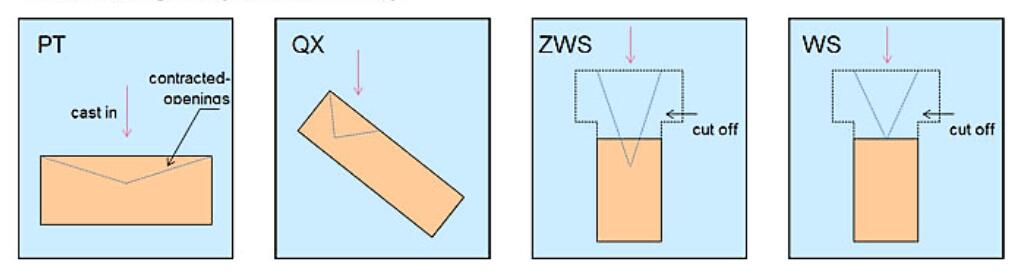

Fused cast blcok casting methord

There have four methods to make fused cast block:PT/QX/ZWS/WS .The different distribution area, quality of shrinkage cavities and dense part are the ways to know which fused cast method the block used.

PT-Normal casting, shrinkage cavities are located on the upper part of block, just under the in-pouring hole.

QX-Tit casting,the fused cast mold is tilting,so the shrinkage cavities spread over the ridge close to in-pouring hole. And the rest part is definitely dense.

ZWS- End casting,The casting track almost like WS is the cast method without shrinkage cavities (ZWS). By using this method, there is a little cavities on the block.

WS-Void free casting, this method is vertical casting with special shrink head, and the shrinkage cavities focus around the shrink head. After annealing, the shrinkage cavities part will be cut off based on the certain sizes. So the block we finally get has no shrinkage cavities.