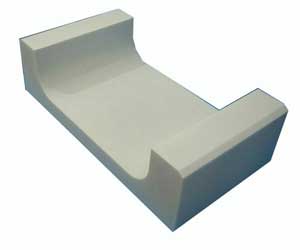

Fused cast alumina brick description

There are three type of fused cast alumina block in huachen refractory factory, that is fused cast alumina α block, fused cast β alumina block and fused cast α-β alumina block.

Fused cast alumina α block:

Fused cast alumina α blockis an bettter choose product for the lower temperature zones of the glass melting furnaces base on its high density, superior corrosion resistance and low blister potential. It is also angood materials for Metallurgical Titanium Furnace because the superior thermal stability.

Fused cast β alumina block

Fused cast β alumina block comprises of a majority of β alumina crystals and a slight portion of α alumina crystals in compact structure. Moreover, the intersected texture of large β-alumina ensures great dimensional stability and great resistance against spalling. Its property of base saturation enables a higher resistance to alkali vapor, thus it has excellent thermal shock resistance and does not form molten droplets. It is the best material for eltingr crown, port crown,feeder channel,ect.

fused cast α-β alumina block

Fused cast α-β alumina block is formed by the compact structure of α alumina and β alumina crystals in a most ideal proportion which is approximately 50% and 50% respectively,where intertwined crystals of both materials result in a very dense structure.

Specifications and applications of Fused cast α-β alumina block

1.Below 1350 ℃, it has excellent corrosion resistance against molten glass and great performance against contamination to molten glass, thus it is very suitable for paving blocks and fore-hearth channel blocks.

2.,When in contact with molten glass, it barely produces any blistering or stones. So, α-β alumina blocks may be widely used in working tank, feeder channels, superstructures and lipstone, etc.

3.In general, in soda-lime container furnaces α-β alumina fused-cast is installed in the Alcove and channel areas, as alternative to AZS fused-cast for Alcoves and as alternative to AZS fused-cast, zirmul, sinter-alumina and other sinter refractories for channels.

Fused cast alumina brick characters

1. Low bulk density, low thermal conductivity, good thermal insulation performance.

2. Refractory category allow direct contact of fire, suitable ofr various atmosphere

3. Good integrity with furnace lining, long service life, easy operation, could be shaped freely

4. Product specification: standard form, normal standard, shaped and special shaped bricks.

5. Can be used in various kilns because of its cheapness and general tray package. Among all of the refractory materials, it is the most widely used.

Fused cast alumina brick Physical & Chemical

Item | Behaviors |

HCR

(α- Alumina)

| HCR (α-βAlumina) | HCR

(β-Alumina )

|

Typical Chemical Composition % | Al2O3 | 98.5 | 94 | 93 |

Na2O | 0.9 | 4 | 6.5 |

SiO2 | 0.4 | 1 | 0.2 |

CaO | 0.1 | 0.1 |

|

Fe2O3 | 0.07 | 0.25 |

|

Crystallographic analysis % | α-Al2O3 | 90 | 44 |

|

β-Al2O3 | 4 | 55 | 99 |

Glass Phase

| 6 | 1 | 1 |